Field Application Examples

The following series of application photos highlight Anderson’s system approach to monitoring and dispensing equipment field installations. Also included are some before and after examples of process equipment that have gone through the Anderson program.

Evaporator - Process Aids

Anderson Chemical manufactures food-grade process aids for large-scale evaporators involved in whey and permeate processing. These process aids often provide improved heat transfer, increased production times, reduced downtime, and reduced acid CIP detergent use and shorter CIP times increasing production turnaround.

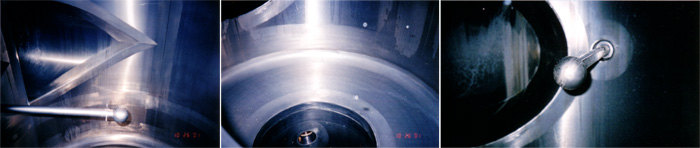

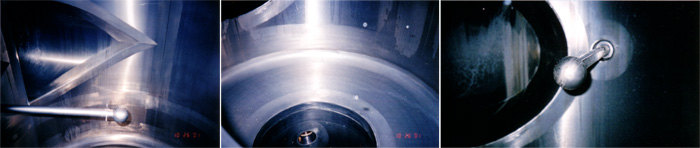

Pictures shown are evaporator internal surface areas of an evaporator utilizing food-grade process aids and post-CIP cleaning. These are shiny clean surfaces.

Evaporator - Cleaning Programs

The following pictures show the top of an evaporator after CIP; the tube chest at the top shows the condition of the product feed tubes.

|

|

| BEFORE. These pictures show dirty tubes from an insufficient CIP Program. |

AFTER. These two pictures show the evaporator tubes after the CIP program was improved according to Anderson’s recommendations. All the evaporator tubes are clean and shiny. |

Membrane Cleaning Programs

Anderson can improve your membrane cleaning program.

|

|

| BEFORE. If your program looks like this, we can automate and improve your membrane automated chemical dispensing and control performance. |

AFTER. Anderson designs and installs systems to reduce labor, improve results and consistency, while lowering overall membrane system operating costs. |

Environmental Programs

|

|

| BEFORE. This picture shows how soiled the cheese making area can become during the course of production. |

AFTER. The following picture shows the excellent results achieved in another system after introduction of the Anderson program. |

CIP Systems

|

|

| BEFORE. Does your CIP “control” look like this? We can take a look at your system, analyze the system with a trained team of experts, and work with you to provide the level of CIP control you require. |

AFTER. CIP performance using Anderson custom-designed equipment will fine-tune your CIP chemical control, providing you with optimal cleaning and sanitizing results. |

Single-Use or Self Circulating CIP Programs

|

|

| BEFORE. Shown here in a dairy/cheese plant is a Milk HTST, Separator, and Holding tubes. To reduce labor and improve results Anderson automated the dispensing and control of CIP cleaning program from labor-intensive to a push of a button. |

AFTER. A new automated system provides a better standard of control and operation. |

Plant Raw Material Storage/Finished Product Areas

|

|

| BEFORE. We can help you with your sanitation program management. The following is a Silo Alcove in need of attention. |

AFTER. The following Silo Alcove is well managed and clean. |

Potable Water Control

Anderson provides the latest in safe, highly efficacious chlorine dioxide technology. Chlorine dioxide will improve your potable water program versus chlorine. We have improved COW water control from TNTC (out-of-control) to consistently <10 cfu/ml.

AFTER. Anderson’s systems are safe, easy, effective, and economical.

Entryway Sanitizing Programs

|

|

| BEFORE. Entryway Foam or Floor Mat Footwear Sanitizing – Do your results look like one of these – tracking dirty water or having a poor foam mat with little to no coverage? |

AFTER. Anderson can improve your facility entryway bacterial barrier with the latest technology giving you the best sanitizing performance and surface coverage possible. We have new and innovative foam sanitizing products, complementing the equipment technology. |

Manual Plant Cleaning Programs

|

|

| BEFORE. Do you need improvements in your environmental and equipment exterior cleaning and sanitizing? We can transform a disorganized labor-intensive practice to “Best Practices”. |

AFTER. This is one small example of Anderson’s manual chemical dispensing system improving operations on the plant floor. Anderson custom design-builds equipment for your facility. |