Sanitation Technologies

A Division Of Anderson Chemical Company

Egg Industry

Anderson has served the Egg Industry for over 40 years now. We feel we can provide professional, forward looking programs that will enhance your plant operations in many areas beyond just sanitation.

Product Line- Egg

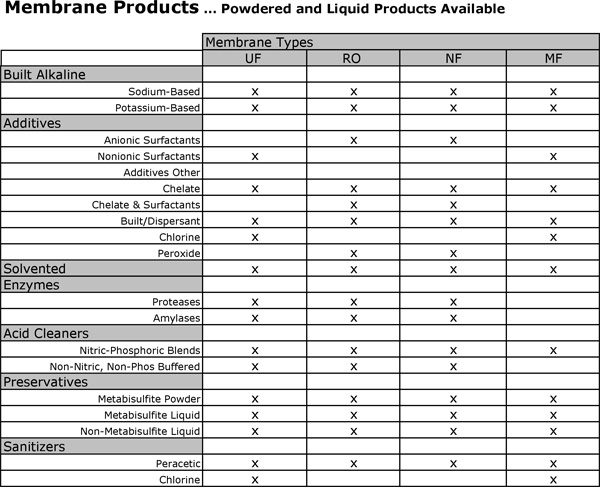

SHELL EGG SANITATION PROGRAMSCIP Cleaners & SanitizersCOP Cleaners & SanitizersShell Egg ProductsMembrane SystemsGeneral & Environmental Cleaners & SanitizersPersonal Care

CIP Cleaners & Sanitizers

PRODUCTS AVAILABLE:

- Non-Chlorinated Alkaline Low-Foam

- Chlorinated Alkalikne Low-Foam

- Acid Low-Foam

- CIP Sanitizers

COP Cleaners & Sanitizers

PRODUCTS AVAILABLE:

- Non-Chlorinated Low To High Foam

- Chlorinated Alkaline Low To High Foam

- Acid Low To High Foam

- General Cleaners

- COP Sanitizers

Shell Egg Products

SHELL EGG CLEANERS:

- Egg detergents are alkaline, contain water conditioners and scale inhibitors, and include defoaming-wetting agents.

- Powdered products may be a combination of caustic soda and soda ash. They may contain inorganic polyphosphates for water conditioning and soil removal. Defoamers may be incorporated.

- Liquid products are based on caustic soda or caustic potash. They may be non-chlorinated or chlorinated.

- Capsule-type (solid) products can provide very good cleaning results.

- In some cases there are plant operating conditions in which capsule-type products do not work well. If there is a lack of sufficient hot water and/or water pressure, then solid capsules or powders may not dissolve well enough.

- One powder product that can work well under most conditions is Egg Cleaner PDF.

NON-CHLORINATED LIQUID PRODUCTS

- Sodium-based liquids are non-phosphated. They may be chelated and/or contain scale inhibitors.

- Potassium-based products may contain detergent phosphates, and/or other scale inhibitors (an approved phosphonate and an approved polymer).

- Each Anderson Chemical product has advantages.

- Potassium-based products may clean the egg washer and its components better and be

more easily rinsed.

CHLORINATED LIQUID PRODUCTS

- Chlorinated alkaline products contain sodium- or potassium-based alkali and detergent components compatible with each chemistry.

- A good choice of detergent will not only clean the shell egg, but also help maintain the washer in good operating condition, minimizing acid descaling requirements (due to mineral build-up in the washer and heating coils).

- Since the mechanical cleaning time is short, the detergent must be effective.

- Well-built alkaline cleaners provide the best results. A recommended premium product is Shell-Brite L-45 Blue. For good results using an economical cleaner Egg-Cel is recommended.

- Liquid cleaners are easy to dispense and control.

- Low-foam chlorinated alkaline CIP (Clean-In-Place) detergents also provide good results. However, the chlorine level is very difficult to maintain at useful levels due to the high soil load and protein levels in the washer solution. A liquid product of this type is Egg-Chlor.

- Alkaline cleaning solutions at high temperatures have a tendency to precipitate minerals present from egg soils and from the wash water hardness.

- Low-cost, poorly built or poorly chelated sodium-based alkali can accelerate the precipitation of hard scale. Waters containing higher levels of iron may also be precipitated, leaving (red or rust-colored) iron films.

- When choosing a shell egg detergent, keep the total labor and descaling costs in mind (total operational costs).

- Eggs enter the washer on mechanical rollers that rotate as they move through the washer unit.

- The (contoured) rollers are typically foam cleaned each day to remove soils they can inhibit the movement of the eggs (soiled rollers can cause dirtier eggs). Anderson’s self-foaming chlorinated alkaline cleaners such as Foment or Bio-Foam (or Bio-Foam SM) are used.

- The washer’s mechanical brushes, spray nozzles (spray arm) and piping should be cleaned on a daily basis. All internal equipment of the washer should be cleaned.

- Due to the high level of protein soils in the wash water (from soil removal and leakers) excessive foam develops in the wash tank.

- The level of foam must be kept down for several reasons: it is unsightly, it can cause the recirculating pump to cavitate, and it decreases the cleaning solution flow to the brushes.

- USDA inspectors may not allow excessive foaming.

- The Anderson technical consultant evaluates the egg washer and checks the reason or reasons for high-foam in the egg washer.

- There may be mechanical causes of excessive foam in the washer.

- Washers kept in a cleaner condition are less malodorous. It keeps the washer and the environmental area surrounding the washer in a more sanitary condition.

- Maintenance personnel will appreciate the difference.

- Acid descaling is reduced.

- Foam cleaning/manual scrubbing labor may be reduced.

DESCALING PRODUCTS

- The condition of the brushes is important; they aid in soil removal. If not kept in a clean condition, increased egg breakage can occur.

- Harsh or aggressive caustic cleaners or strong mineral acids can result in hardened brushes.

- Due to scale (mineral) build-up, the equipment must be de-scaled. Phosphoric acid or sulfamic acid (inhibited) is often used. Blended acids can be used to lower de-scaling costs, as long as they are safe on equipment. Anderson Chemical’s Descale Red is an effective, economical de-scaling

General & Environmental Cleaners & Sanitizers

PRODUCTS AVAILABLE:

- Manual Cleaners

- Self-Foam Cleaners

- Pressure Washers Cleaners

- Environmental Sanitizers

- Foam clean inside and outside of shell egg washers, underneath equipment, floors, walls, etc. using a self-foaming chlorinated cleaner.

- Brush drains with a foaming cleaner, rinse, and sanitize.

- Use mild detergents for the grading machine area. Acid descalers may be periodically needed on grading rollers.

- Use an effective product like Rub Out, in floor scrubbers.

- General Plant Cleaning